Nest / Tray Processing and Treatment

Nest Treatment

Since 2008, in collaboration with the main manufacturers in the pharmaceutical industry of RTU (Ready To Use) formats, Dara Pharma has been investing in the development of new technologies that allow the processing of aseptic products in a versatile, adaptable and compact way, reducing energy consumption and space required on site to gain flexibility.

In 2008, filling and closing in Nest was the first and foremost development in this regard. However, it soon became clear that these products could not be treated as independent pharmaceutical processing equipment, but rather as complete lines in which cross-contamination had to be evaluated as a whole.

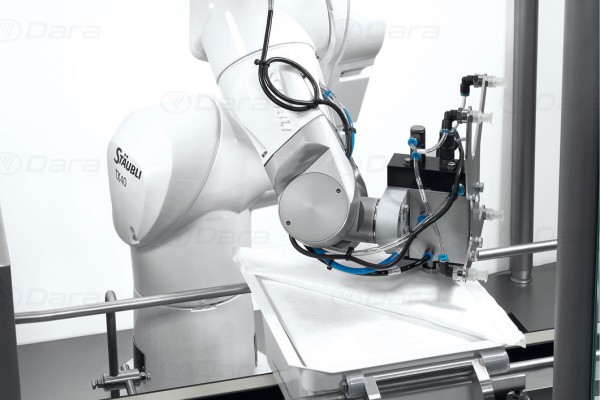

Under this premise, different complementary equipment is created to perform processes like debagging, delidding, denester, renester, and loading and unloading systems for freeze dryers, which complete and modulate our RTU lines.

The evolution and increasing use of RTU formats led major manufacturers to evolve the Nest concept, thus creating the Tray format, which could operate with vials and cartridges in larger clusters. This made it possible to reduce product cost and, at the same time, achieve higher production speeds.

As a pioneer in the development of these specific systems, Dara Pharma has once again surprised the market with the introduction of the “Combi” RTU lines. These pharmaceutical equipment solutions allow both Nest and Tray processing, denesting the product at the source, and managing vials, syringes and cartridges individually, according to the customer's needs for each application.

Format range

Products

Process steps

Output range

Always at your disposal!

We look forward to assisting you with your projects and answering your questions and suggestions. Fill in this form and we will contact you as soon as possible.